24/7 Lift Maintenance Repair: Trigger and Effective Service

Wiki Article

Pro Tips for Preserving Your Lift in Top Problem: A Thorough Overview

Making sure the optimal performance of a lift system is crucial for a risk-free and reliable operation in numerous settings, from commercial storage facilities to business buildings. By sticking to an organized upkeep program and preemptively addressing possible issues, lift owners can minimize costly downtime and safety and security risks.

Relevance of Regular Upkeep

Normal maintenance of your lift is critical to ensure its ideal efficiency and longevity. By adhering to a normal maintenance routine, you can recognize and address prospective concerns prior to they escalate into expensive repairs or unexpected downtime. Regular maintenance tasks such as lubricating relocating components, checking for damage, and checking hydraulic systems can assist protect against malfunctions and make sure secure procedure.Neglecting routine upkeep not just endangers the efficiency of your lift but likewise presents safety and security threats to customers and home. Parts that are not effectively kept might fail unexpectedly, resulting in mishaps or damage to the lift itself. Additionally, attending to concerns beforehand via upkeep can expand the life-span of your lift and minimize the possibility of significant malfunctions.

In enhancement to enhancing security and performance, routine maintenance can also conserve you cash in the lengthy run. By purchasing precautionary maintenance measures, you can avoid pricey fixings or substitutes that might develop from overlooking the upkeep of your lift. Overall, focusing on normal maintenance is vital for taking full advantage of the performance and longevity of your lift system.

Leading Elements to Check

Furthermore, pay close interest to the lift's security functions, such as emergency situation quit buttons, security sensors, and interlocking systems, to ensure they are functioning correctly. Frequently check the lift shaft for particles or obstructions that could impede the movement of the lift car.

Proactive Troubleshooting Strategies

By tracking metrics such as lift speed, electric motor temperature, and power intake, maintenance groups can identify early indicators of potential problems and take rehabilitative actions before they rise. Additionally, applying a preventive maintenance schedule that includes lubrication of relocating components, testing of emergency brakes, and calibration of sensing units can proactively resolve common lift system issues.In addition, investing in training programs for maintenance personnel on fixing strategies specific to the lift design set up can encourage them to detect and deal with problems quickly. By remaining in advance of possible problems company website through proactive troubleshooting, lift operators can make sure a smoother and extra reliable operation while reducing the danger of unforeseen malfunctions.

Crucial Lubrication Practices

Implementing proper lubrication practices is essential for guaranteeing the smooth operation and durability of lift systems. Routine lubrication helps in reducing friction in between relocating components, stopping damage that can bring about pricey repair services and downtime. When it involves raise upkeep, complying with a stringent lubrication routine is vital.Choosing the right lubricating substance is the initial step in reliable upkeep. Different parts of the lift system may call for certain sorts of lubricating substances, such as grease or oil. Consult the supplier's guidelines to figure out the suitable lubricating substances for every part.

Address any type of problems without delay to prevent additional damages and make certain the ongoing smooth operation of your lift system. By prioritizing appropriate lubrication methods, you can prolong the life-span of your lift and maximize its efficiency.

Safety Steps for Lift Operators

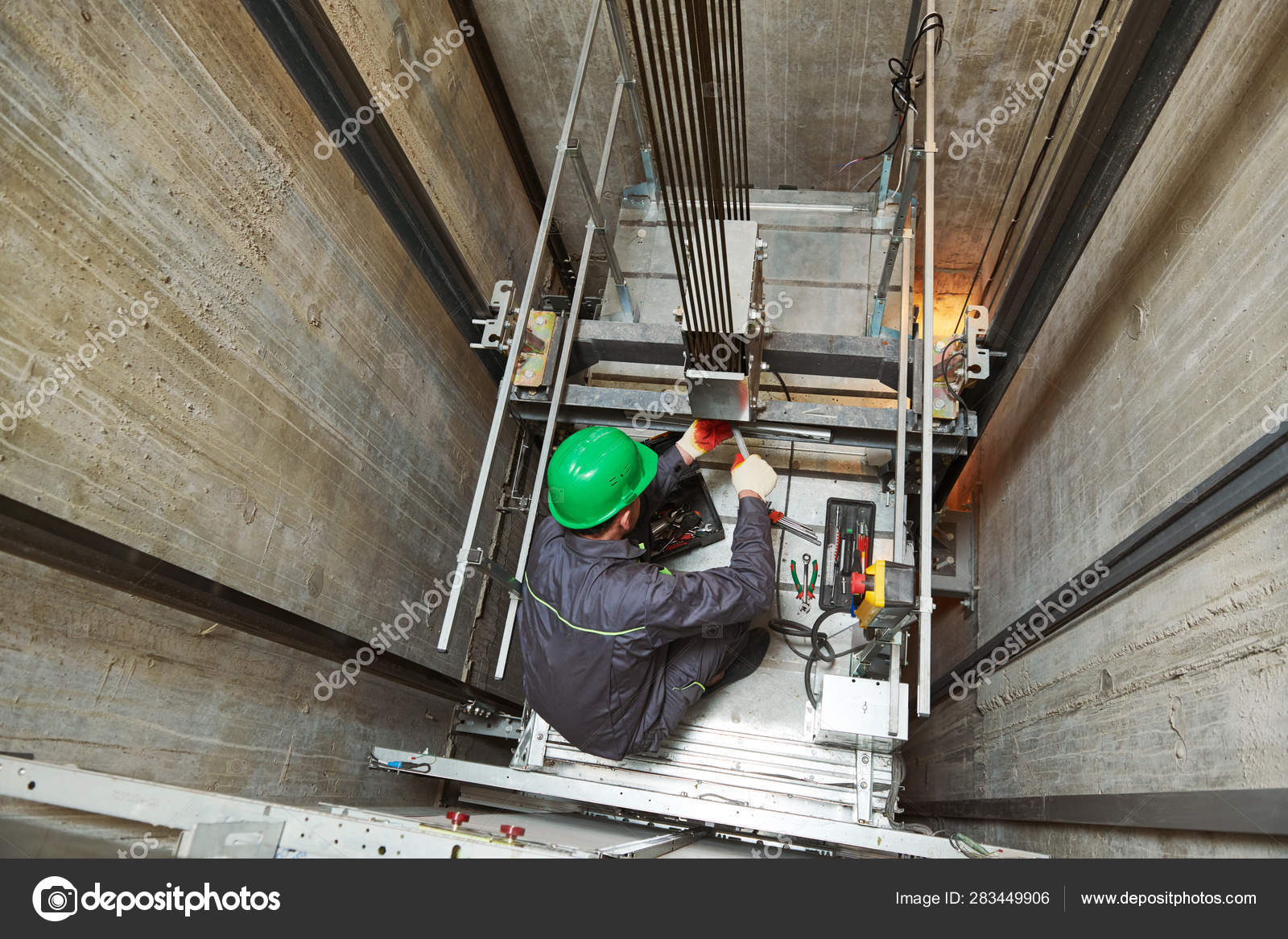

In order to maintain a secure working setting and maintain functional performance, lift operators need to rigorously stick to recommended safety methods, together with prioritizing crucial lubrication methods for optimal lift efficiency. Safety actions for lift operators are crucial to protect against mishaps and make certain the smooth functioning of the lift system.Furthermore, lift drivers must focus on individual protective tools (PPE) such as safety helmets, handwear covers, and harness when operating at heights or taking care of heavy lots. Clear communication among drivers, maintenance service technicians, and other workers is vital to stop misconceptions that could cause accidents. Finally, drivers must stay vigilant, focused, and stay clear of distractions while operating the lift to make certain the safety of themselves and others around.

Verdict

Finally, preserving a lift in leading problem is crucial for making sure safety and security and efficiency in operations. Routine maintenance, detailed inspections of essential elements, aggressive troubleshooting, correct lubrication techniques, and adherence to precaution are necessary for lengthening the life-span of the lift and preventing accidents. By following these guidelines, lift operators can guarantee the continued performance and safety and security of like it their equipment.By sticking to a structured upkeep routine and preemptively attending to possible concerns, lift proprietors can minimize pricey downtime and safety and security threats. Routinely examine the lift shaft for debris or obstructions that could restrain the activity of the lift car.In order to maintain a secure functioning atmosphere and support operational efficiency, lift drivers have to rigorously stick to prescribed safety protocols, together with prioritizing important lubrication practices for optimal lift efficiency. Security steps for lift operators are crucial to protect against crashes and make sure the smooth functioning of the lift system. Normal upkeep, extensive evaluations of key parts, positive troubleshooting, proper lubrication techniques, and adherence to security measures are necessary for extending the lifespan of the lift and stopping accidents.

Report this wiki page